|

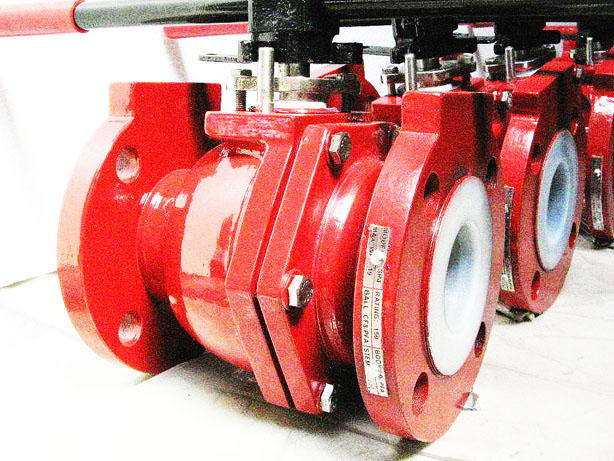

Design Std. |

BS5159, EN ISO 17292 (BS 5351),

API 599 |

|

Face to Face |

ASME B16.10 |

|

Testing Std. |

EN 12266-1 (BS 6755-1) |

|

Body & End material

|

DI, WCB, CF8, CF8M, etc. |

|

Ball Material (Integral Stem) |

17-4PH |

|

Body & Ball Lining |

PFA / FEP |

|

Seat & Seal |

PTFE |

|

End Connection |

Flanged |

Dimensions

-

DN15-150 Dimensions

-

DN15-150 |

Send

Inquiry Send

Inquiry

|

|

PFA is developed

as a melt processable fluoropolymer, it is a co-

polymer of tetrafuoroethylene and

perfluoroalkoxy monomer. It has excellent

mechanical strength outstanding dielectirc

properties & is unaffected by virtually all

solvents & chemicals even at high

temperature of 240°C to 260°C.

Processing

Polymers such as PFA by injection molding is

extremely critical as the process requires close

monitoring with controlled heating and cooling

of the assemblies during the entire molding

stage. Our lining technique its own advantages

over the conventional method of lining where

Transfer Molding System are used.

Lining specifications:

Lining material - PFA

Lining material - 3 - 4 MM

Test pressure:

Shell - 30 bar

(Hydro.)

Seat -

22 bar

(Hydro.)

Seat -

6 bar

(Air)

Spark test -

100% Spark Test at 10 KVA

for all

lined parts in contact of fluid

Industry

applications:

-

Chemical

processing

-

Petrochemical

processing

-

Environmental

hazards

-

Pulp & paper

-

Power generation

-

Demin water

plants

-

Mining & metal

refining

-

Pharmaceuticals

-

Food & beverage

-

Iron &

steel

-

Sterile

systems

Media

applications:

-

Aggressive /

corrosive liquids and gases

-

HCL

-

Media /

applications include:

-

Bleach

-

Brine

-

Chlorine

-

Herbicides

-

Hydrochloric

acid

-

Sulfuric acid

-

Waste acids

-

HF Acid

-

For more

information please check factory

Feature:

-

Low Torque

for Easier Operation

-

2 Piece Body,

Full Bore

-

Floating Ball

Seat Design

-

Bubble-tight

Shut-off

-

PFA

Linings of

≥2.5mm

Thickness

-

Stem Packing

Protection

-

Metal to

Metal Body Joints

-

Anti-blow Out

Stem

-

Easily

Replaceable Seats

-

Stainless

Steel Investment Casting Body and Cap

-

Inspection

and Testing to API598

-

Thicker

Liners for Vacuum Applications

-

100% Liner

Testing

-

100%

Hydrostatic, Seat, Stem and Torque Testing

-

High Purity

Cleaning (Oil Free) (Optional)

-

Clean Room

Assembly & Testing (Optional)

|