|

|

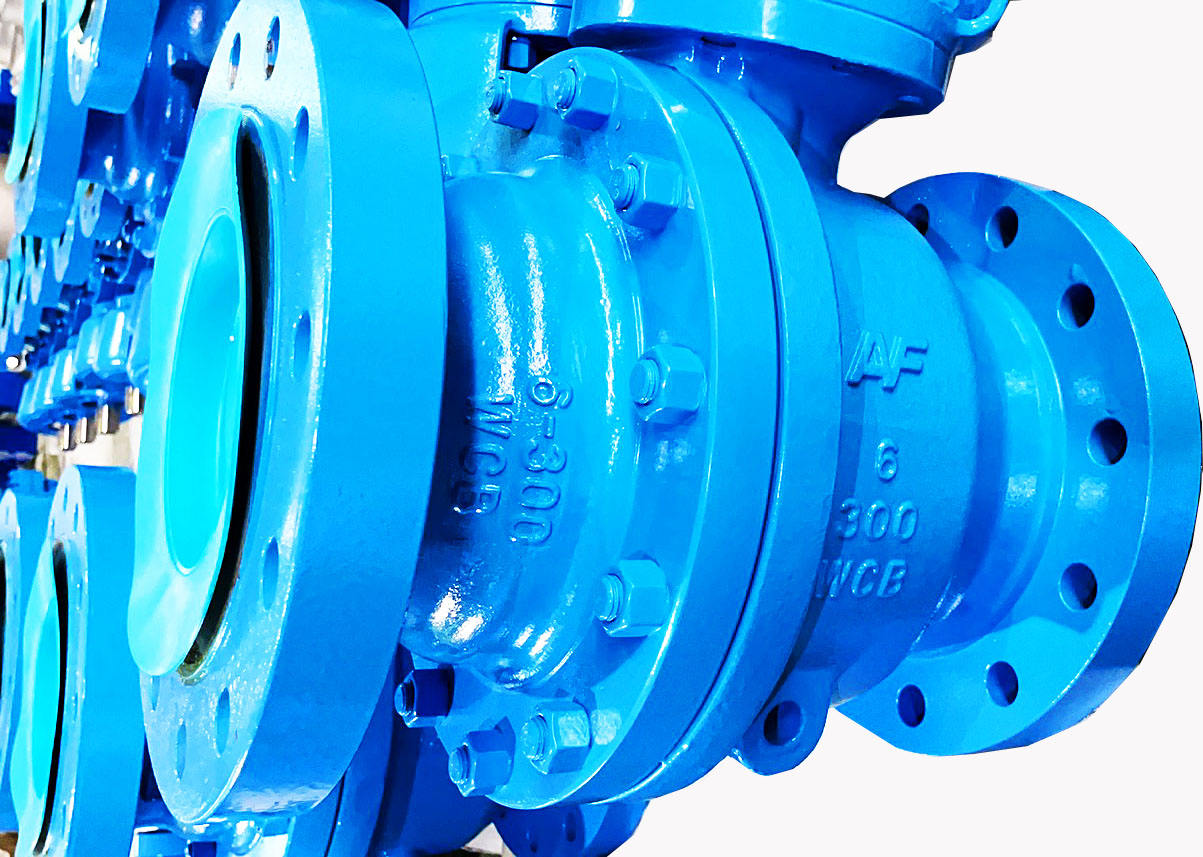

Flanged

Valve / ANSI

AF-50M

Metal Seated

Ball Valve - Floating or

Trunnion

|

|

Design

Std. |

API 6D, API 608, ASME B16.34 |

|

Face to

Face |

ASME B16.10 |

|

Flange

Dimension |

ANSI B16.5 |

|

Testing

Std. |

API 6D, API 598 |

|

Pressure Rating |

Class 150 -

2500 |

|

Metal

Seat & Ball |

SS304/SS316+ Nickel alloy |

Dimensions Dimensions

|

Send Inquiry Send Inquiry

|

|

6" Class 300

Metal Seated Trunnion

Ball Valve

8" Class 300 Metal Seated

Trunnion

Ball Valve

Actuated

1/2" - 4" Class 150 - 300

Metal Seated

Floating

Ball

Valve

AF-50M 2-pc high

performance

metal

seated ball

valve with

ISO

mounting

pad

is

designed

for

use

in

high

temperature,

abrasive,

and

high

pressure

media in

power

generation,

petrochemical,

mining, and pulp

& paper

industries.

To

stand out

from other

economic

valves

in

the

market,

valve

structure

& wall

thickness

is fully comply to ASME B16.34

standard

on

Class 150 & 300(PN16/40)

construction.

The

structure

ensures

safety

in

the

high

performance

application.

Standard

material for

metal

seat

& ball

is

Co

element

(known

as

Stellite).

The

Co

based

material

is

good

at hardness,

corrosion resistance

and

stable

under high temperature.

The

patented unique

split

seat

design is

perfect to

seal the

leakage

from

& over

the seat

area to

meet

at

least

Class

V

leakage

class.

AF-50M

metal

seated ball

valve

is

uni-directional

shutoff as standard.

Features:

-

2-Piece Construction of Superior Performance

-

High Quality Investment Casting

-

Inconel Spring

provides better sealing function

-

Blow-out Proof Anti-static Stem for Max. Safety

-

Live Loaded Adjustable Stem Packing

-

ISO 5211 Mounting Pad for Easy Automation

-

Uni-directional

design

Option:

-

Fire safe design

-

V-Ball

for flow control

-

Stem Extension

-

Special Alloy on Body / End cap / Ball / Stem

|

|

Design

Features:

-

Advanced Hardening Technology

for Ball & Seat

Metal seated design

has been employed perfectly for the ball and seat, which has

also adopted the advanced hardening technologies, such as

ultra-sonic spray coating, nickel base spray welding, surface

specially hardening, Stellite spray welding, ceramic material

with high strength and hardness, and so on. Surface hardness

of the ball and seat may generally reach more than HRC60,

maximum is up to HRC74, and application temperature of the

material may be up to 540℃, maximum is 980℃. Combining

strength of the material gets to more than 10000 PSI. Besides,

the surface materials possess very good resistance properties

of friction and impact. Metal seated ball valves are suitable

for use in most critical working conditions.

-

Preventing Valve from Stuck under High

Pressure

In the case of high

temperature working condition, valve seat and ball get stuck

easily due to heat expansion, and cause problem opening valve.

Our metal seated ball valves employ the patented design of

beveling spring loading, which absorb the heat expansion of

parts with the beveling spring. So it ensures that the valve

would not get stuck and can be opened and closed easily in the

Case of high temperature condition.

-

Excellent Tightness Function

A unique technique has been

employed for the ball grinding, which makes ball surface

extreme round and smooth by rotating the ball and grinding

apparatus at different directions in space. The tightness

function of the valve meets completely and exceeds the

standard requirement.

Metal to metal sealed

structure has been adopted for the valve sealing surface

design. Packing is designed with graphite, and gasket is

designed with stainless steel, plus graphite to assure

reliable tightness even under fire condition.

Metal to metal sealed

trunnion ball valve is in general of the front ball sealing

structure. Actually, two seats of the metal to metal sealed

trunnion ball valve can both cut off the medium separately at

inlet and outlet to realize double-block function. When the

valve is closed, the body cavity and both the bore ends can be

blocked with each other even if both ends of the valve are

under pressure at the same time. whereas the medium left in

the body cavity may relieve through the relief valve. Our

metal to metal sealed floating ball valve is of behind ball

sealing structure, employing in general single direction

tightness. The flow direction is indicated on the valve body.

If specially required by customers, our patented bi-direction

sealing design may be selected.

Applicable

Standards & Specifications:

- Design and Manufacture : API 6D, API

608, ASME B16.34, MS SP-7S, BS 5351, BS6364,

ANSI/AWWA C507, BFCI 70-2, ISO 5211

- Connection Ends : ASME B16.5, B 16.47,

API 605, MSS SP-44,

ISO 7005-1, JIS B2238, BS 12627, ASME B16.25, ASME B16.11,

BS 12760

- Face to Face Dimension : ASME B16.10,

ISO 5752, BS558, BS12982

- Inspection & Testing : API 6D, API 598,

API 607/API 6FA, BS6755, BS 12569,

MSS SP-61

- Nominal Pressure Rating : Class 150 -

2500, JIS 10K - 20K, PN10 - 420

- Nominal Diameter or Bore : NPS 1/2 - 10, DN 15 - 250

- Applicable Temperature: -196 °C to 540

°C

- Manual, Worm Gear, Pneumatic, or

Electrical Operations

|

|

|